This project of Buta Steel Company opened up broad opportunities for economic development

As one of the largest steel companies in Europe, Buta Steel Company LLC keeps on introducing innovations and advanced technologies into production in order to contribute to the world’s economy. Modernized Buta Steel Company has implemented a unique project for the region.

It is possible to produce a greater number of high–quality products in the shortest time possible with fewer losses at a new generation of Continuous Casting Machine (CCM) with a radius of 10,25 m. The new production line is capable of casting square billets in standard sizes and on order lengths of 6, 9, 12 m, width 125-125 mm and 150-150 mm, and round billets with diameters from 130 to 250 mm depending on the mark of the surplus steel. The steel content is purified from non–metallic compounds after installing a vacuum degassing system as a continuation of the process. Here, it will be possible to produce higher quality steel for machine–building, military–defense industry, aviation and etc., areas alongside construction. Casting high-density round billets at the plant will also facilitate the production of pipes durable to high depth pressure utilized in the oil production industry in particular.

In general, the commissioning of the new CCM will positively influence production capacity, revenues of the modernized company, and further improvement of the social welfare of its employees. Electromagnetic mixers have been installed at crystallizers designed for round billets to enhance steel dispersive capacity, gain even smaller sizes of crystal grains, and achieve higher quality. This helps the steel to attain an even higher disperse structure when molten metal is cast in copper molds and ensures higher quality.

Further, our production site in Sumgait city has enabled us to produce only seamless pipe size 114 mm out round billet 130 mm until the present, whereas the new CCM will make it possible to produce all marks of pipes up to 219 mm and this means a threefold increase in the production capacity. The company’s overall export capacity will increase with that. So, while BSC’s monthly production capacity is only 2, 000 metric tons at present, this figure will reach 7-9, 000 tons on average by using the capacity of the new CCM.

It is noteworthy that BSC currently owns 2 melting shops comprising one 60-ton and one 30 tons electric arc furnaces, 3 rolling mill lines, one seamless pipe producing mill line, one spiraled welded pipe producing mill line, and a mini plant producing shaped items, and one oxygen plant.

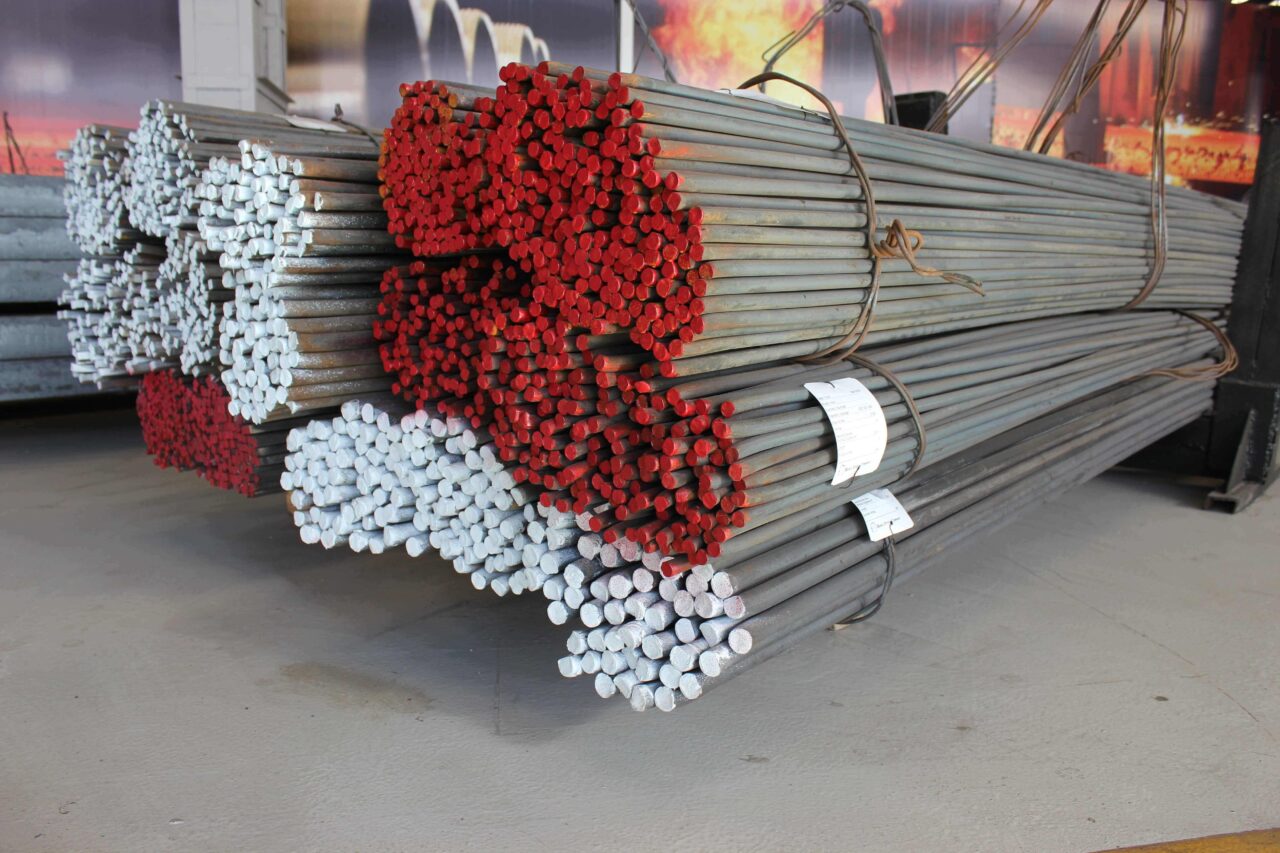

Buta Steel Company produces high-quality rebar, wire rod, square and round billets, seamless and spiraled welded pipes, including branded shape casts. It is also possible to produce channel, angle, and I-beam.

Please note that BSC products have also been exported to Turkey, Georgia, Kazakhstan, Russia, Turkmenistan, Spain, Italy and etc., countries on top of the high demand in the country.

“Buta Steel Company” – steel foundation of economic development!